Our Approach

At MAKAR Timber Engineering we believe great buildings and places not only improve lives but they contribute to solving the big, seemingly intractable issues of our time.

It’s now widely recognised that the only plausible way to deliver a net zero carbon built environment is through the use of timber-based systems. This is what drives our pioneering approach. Our unique off-site construction method uses natural and local materials to create beautiful, healthy buildings and contribute to a vibrant rural economy.

“People don’t buy what you do, they buy why you do it”

MAKAR and now MAKAR Timber Engineering are at the leading edge of sustainable Design for Manufacture and Assembly, with twenty years of experience and expertise forming six key areas of innovation:

Scottish Grown Timber

-

A fundamental tenet of our operation has been the use of Scottish-grown timber, thus adding value to one of the country’s key natural resources.

The key species utilised are Sitka spruce (in natural Structural Insulated Panels (n-SIPs), European larch (for external cladding) Douglas fir (for post and beam frames and other large components).

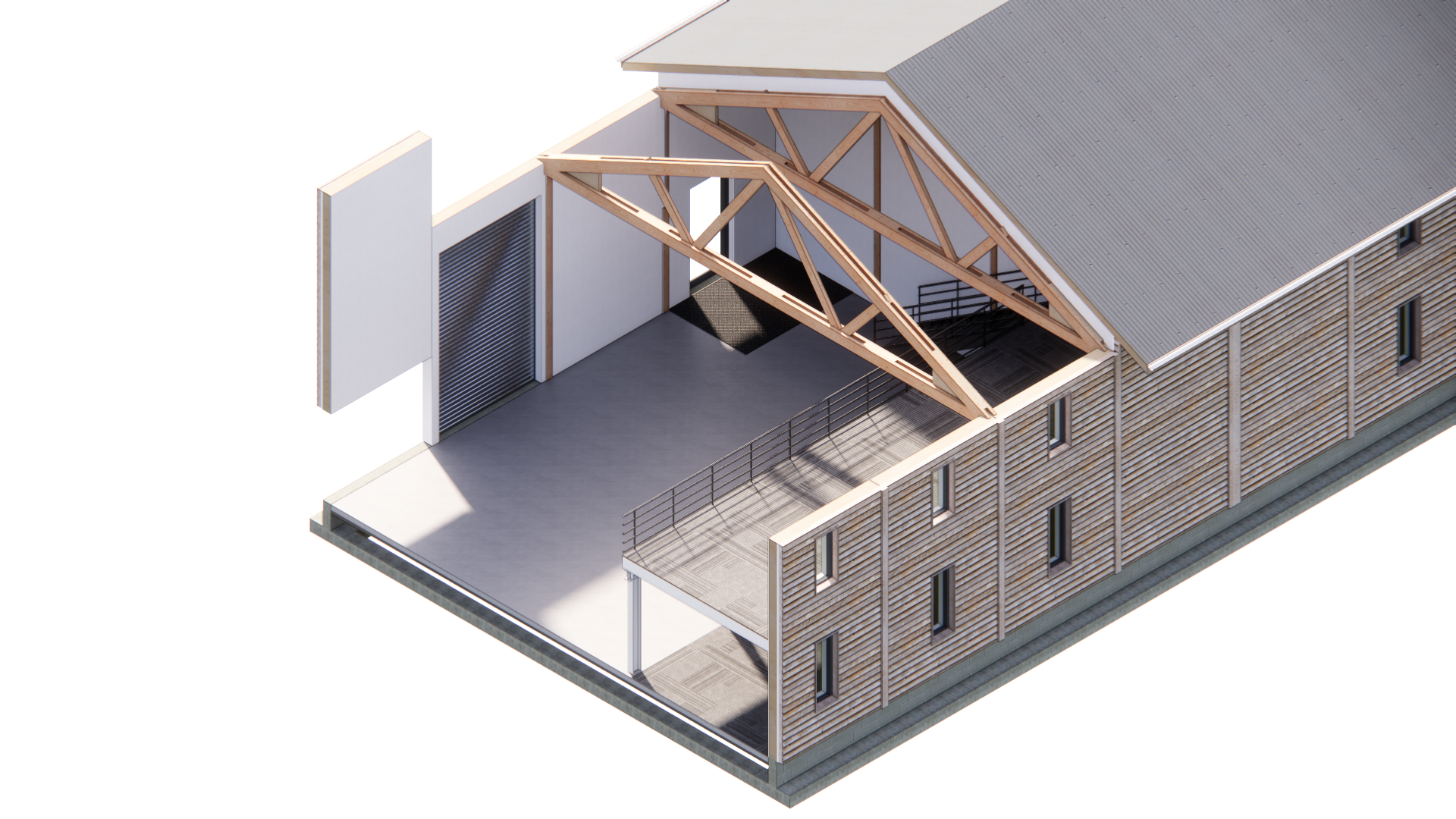

Off-site Manufacturing

-

Our ability to “build” in the workshop, dramatically reduces the assembly time of buildings on site and significantly improves the consistency and quality of our product.

Net Zero Components

-

Our timber intensive buildings form part of the global carbon sink. Studies on MAKARs home buildings, which can be carried over to our approach to commercial builds, confirm that these homes are Net Zero carbon on delivery.

For example, following expert analysis by the School of Environmental Studies at the University of East Anglia, the embodied carbon in a MAKAR home was found to be 27% lower than a comparable timber frame house (typical of Scottish volume house builders); and 39% lower than a Passivehause with brick walls.

Reducing Energy Demand

-

Within both our residential and commercial builds we have developed processes and products that reduce energy demand in homes through high standards of insulation and performance.

For example, In recent years innovations in our system such as the use of wood-fibre insulation have contributed to projects being able to achieve Passivhaus.

Natural Materials

-

Our approach rejects the steel structure norm for commercial bodies because of its high embodied carbon content. We also minimise or exclude the use of materials containing toxic adhesives.

A central feature of our work has been the development of a closed load-bearing panel natural Structural Insulated Panel (n-SIP) system that uses natural materials throughout - untreated Scottish-grown timber and cellulose insulation, either recycled paper or wood fibre.

Passivehaus Standard

-

There are very few businesses in the UK which are able to design and build a Passivhaus, and even fewer can do it using a standardised off-site approach, such as our n-SIP system.

Passivhaus buildings provide a high level of occupancy comfort while using very little operational energy for heating and cooling. They are built with meticulous attention to detail, and a rigorous design and construction approach following the principles developed by the Passivhaus Institute in Germany and certified through an exacting quality assurance process.